preface

At present, the main desulfurization technology with wet method and dry method two kinds, coking industry most of coke oven gas desulfurization by wet method, but the desulfurization process equipment and adopted by the catalyst is varied. The main are: improved ADA, HPF, AS, TH, 888, such AS the use of different process and catalyst present competing doo-yan desulfurization technology. Wuhai West Coal Chemical Company has a tamping coke oven with 2x72 holes and 4.3m tall carbonation chamber, with an annual output of 1 million tons of metallurgical coke. The deceleration section adopts 888 wet desulphurization process, which was put into operation on December 18, 2010, and has essentially achieved the original design purpose since its construction: H2S content behind the tower ≤20mg/m3. Reflect the process optimization, efficient equipment, convenient operation, both environmental protection and energy saving characteristics.

1 Device Features

The 888 wet desulfurization process mainly adopts the combination of empty spray tower and packed tower. The empty spray tower is used for pretreatment to absorb approximately 80% of H2S and HCN, and then two packed towers are used for further refined desulfurization, so as to solve the problem of tower blocking easily in the usual desulfurization process. Moreover, in addition to the excellent work of the empty jet tower in the case of not easy tower plugging, it can also prevent the erosion of oil, naphthalene and other impurities in the subsequent process. After the air jet tower desulfurization liquid is eroded, a satisfactory desulfurization effect can also be obtained by adjusting the packed tower desulfurization liquid. Thus, the time to deal with the desulphurization liquid of the air spray tower is given and the deceleration work is guaranteed to proceed properly. Desulfurization liquid heavy regeneration through the liquid heavy pump pressure into the ejector jet suction oxidation regeneration; the sulfur foam produced in the regeneration tank was filtered by a microporous ceramic filter to produce sulfur paste. The main technological process is as follows:

2 Special ejector for PSC desulfurization and regeneration tank

The special ejector (PSC type) for desulfurization regeneration tank is used in the process of heavy liquid regeneration system. Injector used in gas-liquid mass transfer can give full play to the principle and flow process, the advantages of desulfurization fluid at elevated speed through the injector nozzle to form local pressure suction air jet, at this time because of two-phase fluid immediately with high-speed dispersion in high-speed turbulent state, the gas-liquid interface is considerably increased and continuously updated, so the mass transfer process is extremely quick. The sulfur particles formed by rapid and effective regeneration and oxidation of the deceleration solution are overflowed by flotation in the regeneration tank, so as to complete the transformation of the deceleration solution from rich liquid to poor liquid.

3. Pre-desulfurization that point

Wet oxidation using packed tower as the absorption tower type has numerous disadvantages, especially for coke oven gas. First of all, the imported sulfur is higher, and then the temperament is unclean, so it determines the wet desulfurization is easier to block tower than other chemical industries. In addition, because of the elevated sulfur, it is usually two-stage three-stage series, which makes the impact of system resistance on the whole production more prominent. Drawing on the successful experience of the empty tower technology of the semi-water gas desulfurization tower of numerous nitrogen fertilizer enterprises, Dongshi Company takes the lead in adopting the empty tower technology in our coke oven gas pre-desulfurization tower. From the actual operation, the desulfurization efficiency of the empty tower alone is more than 70%, which not only ensures the desulfurization efficiency, but also practically no resistance of the empty tower. It is beneficial to the resistance reduction and stable operation of the whole system.

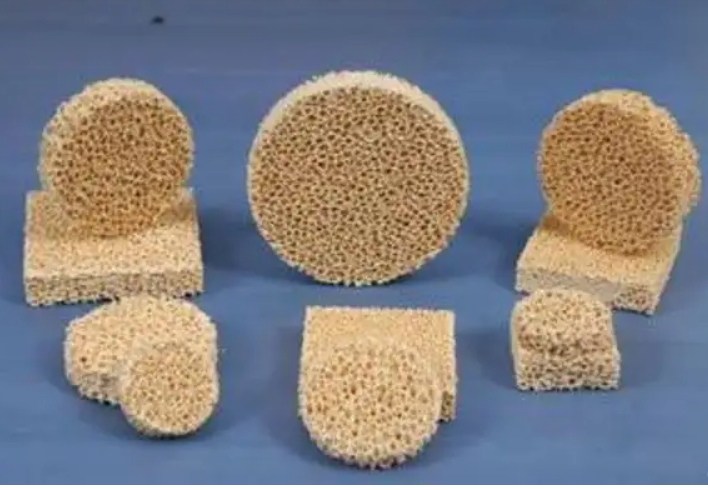

Sulfur recovery equipment

In this process, the sulfur foam is treated by DS type ultrafine cellular ceramic foam filter . This machine is according to the principle of capillary action, in combination with nano ceramic technology developed high-tech solid-liquid separation products, he on the basis of the desulfurization liquid components and each component of the special physical and chemical properties with different ultra micro hole in the case of a component does not affect the solution will be frozen sulphur filtering sulfur foam, forming filter cake bagging sales can also directly into the sulfur melting kettle melt sulfur, It has the advantages of high filtration efficiency, low production cost, energy saving and consumption reduction, clean and environmental protection, plus the automatic control system to realize the automatic continuity of filtration, discharge, discharge and other processes, greatly simplifying the operation and saving labor.

5 Desulfurization catalyst

The process uses 888 series JDS coke oven gas special deliveries. Because the catalyst has a large sulfur capacity (0.25 ~ 0.40g/L), excellent chemical stability, excellent thermal stability (2000C does not decompose), itself non-toxic and non-corrosive, stable activity of long life, can remove inorganic sulfur and organic sulfur and additional advantages in production to maintain 20~30ppm concentration can achieve the purpose of catalytic regeneration. It has a strong regeneration ability so as to effectively save the amount of soda ash and achieve the purpose of reducing the operation cost.

6 Problems Exist

6.1 The ejector has backspray phenomenon

When the pressure fluctuates or the pump stops, the injection of desulphurization liquid from the regenerative tank ejector may be caused by the low inlet pressure of the instantaneous ejector. Although the time is short, it also causes certain pollution to the environment. In the future, it is prepared to lead the air inlet to the centralized recovery equipment and then back to the regeneration tank.

6.2 The filter plate of the filter is easy to crack.

In the initial use of the filter, the filter plate frequently cracks, which may be caused by unstable water pressure during washing and incomplete cleaning. Later, after exploring the experience and mastering the operation method of the filter, the situation was improved.

6.3 The ability of the catalyst to resist oil impurity erosion needs to be improved.

When the tar content is high in the deceleration section, it is not obvious at the beginning, and then the catalyst activity decreases definitely.

7 conclusion

In short, the optimized 888 DESULPHURIZATION device, through several months of production practice, has shown greater advantages than similar process equipment, with elevated efficiency, energy saving, environmental protection, stability and additional advantages.